CEO at 4DBC Group

The Comprehensive Guide to CubeSat Structure: Revolutionizing Orbital Missions with KSF Space Tech

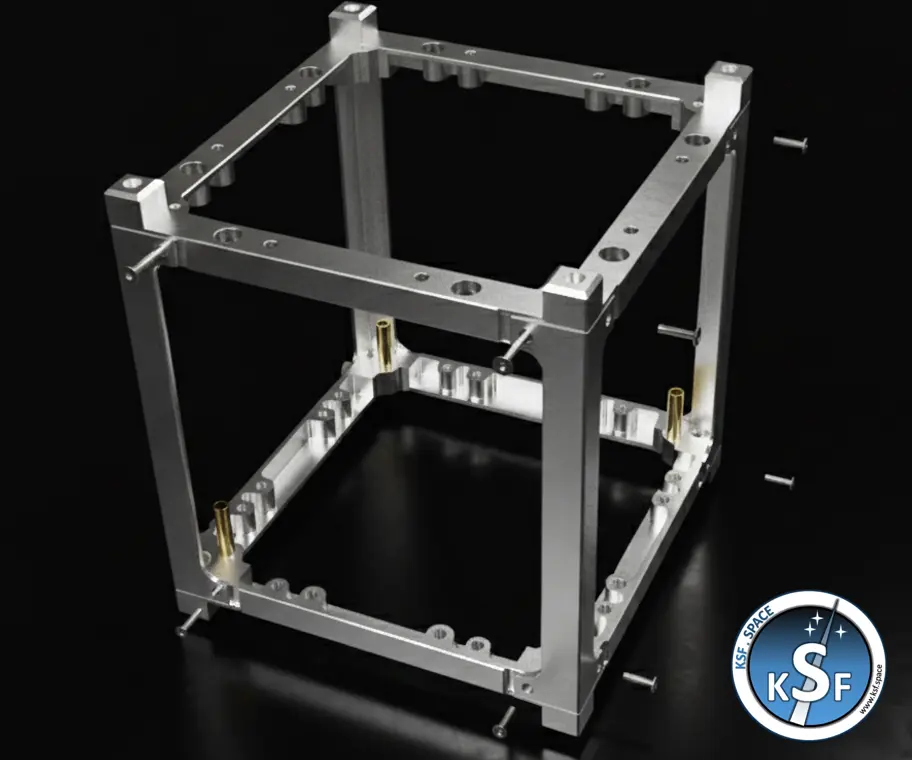

In the modern aerospace landscape, the cubesat structure has evolved from a simple mechanical enclosure into a high-performance system critical to mission success. Whether you are launching a university experiment or a commercial constellation, the structural foundation of your satellite dictates its thermal stability, mechanical survival, and payload capacity.

At KSF Space, we specialize in democratizing space access by offering two distinct, high-performance structural paths: Advanced PA11 Polymer and Aerospace-Grade Aluminum. This guide breaks down why our technology is the preferred choice for modern NewSpace developers.

Optimizing Your Mission with the Right CubeSat Structure

The “U” standard (10x10x10 cm per unit) ensures your satellite fits universal deployers. However, what happens inside that unit depends entirely on the cubesat structure you choose. KSF Space offers 1U, 2U, and 3U configurations designed to balance mass, volume, and durability.

The 1U CubeSat Structure: Compact and Reliable

The 1U is the fundamental building block of the CubeSat ecosystem. Measuring 10 cm on each side, it is ideal for technology demonstrations and academic research. Our 1U cubesat structure provides a high volume-to-mass ratio, ensuring that every milligram is used for your payload, not just the box.

The 2U and 3U CubeSat Structure: Scaling for Success

As missions grow in complexity, the 2U (20 cm) and 3U (30 cm) frames provide the necessary “real estate” for advanced propulsion, large battery arrays, and deployable solar panels. The KSF Space 3U cubesat structure is specifically engineered to survive the intense axial G-loads of modern launch vehicles like the SpaceX Falcon 9 or Rocket Lab Electron.

Material Innovation: PA11 vs. Aluminum CubeSat Structure

Choosing the right material for your cubesat structure can save thousands of dollars in launch costs and months of lead time.

PA11 with Multi Jet Fusion (MJF) Technology

Our PA11 structures are manufactured using HP Multi Jet Fusion (MJF). This isn’t your standard hobbyist 3D printing; it is an industrial powder-fusion process that creates near-isotropic parts.

Mass Efficiency: PA11 is roughly 40% lighter than aluminum. In a industry where launch costs are calculated by the gram, this is a game-changer.

Surface Finishes: We offer a Grey Raw finish for rapid prototyping and a Black Smooth (vapor-honed) finish for flight. The black smooth finish improves thermal emissivity and meets NASA’s strict low-outgassing requirements.

Impact Resilience: PA11 is more ductile than traditional polymers, allowing the cubesat structure to absorb mechanical shocks during separation.

Aerospace-Grade Aluminum Structures

For missions requiring maximum thermal conductivity or electromagnetic shielding, KSF Space offers CNC-machined Aluminum structures.

Thermal Management: Aluminum acts as a superior heat sink, ideal for high-power transmitters.

Hard-Anodized Rails: Our rails are treated to prevent “cold welding” inside deployers, ensuring a smooth release into orbit.

Compliance and Verification: Designed for the Launch Pad

Every KSF Space cubesat structure is designed with the NASA-GSFC-STD-7000 (GEVS) framework in mind. This ensures your satellite isn’t just a model, but a flight-ready asset.

Thermal and Structural Analysis

We utilize advanced SOLIDWORKS Flow Simulation to verify our designs.

Thermal Margins: Our structures are tested to maintain a ±10°C margin relative to predicted orbital temperatures.

Factors of Safety: We adhere to a 1.4 Factor of Safety for ultimate loads, ensuring the cubesat structure remains intact through Max-Q.

Vacuum Stability: Our PA11 material is verified to have a Total Mass Loss (TML) of less than 1.0%, protecting your optical payloads from contamination.

Frequently Asked Questions (FAQ)

Q: Is a polymer cubesat structure really safe for space?

A: Yes. When manufactured with MJF (Multi Jet Fusion), PA11 has the structural density and isotropic strength required to handle launch vibrations. It is a proven material used in various high-stress aerospace applications.

Q: What is the lead time for a KSF Space 3U structure?

A: Our PA11 cubesat structure options typically ship in 1-2 weeks, while custom Aluminum frames ship in 4-6 weeks. This is significantly faster than the 12-week market average.

Q: Can I mount standard PC/104 boards in these structures?

A: Absolutely. All KSF Space structures are fully compatible with the PC/104 mounting standard and the Cal Poly CubeSat Design Specification (CDS).

Q: How does the “Black Smooth” finish help my satellite?

A: The vapor-honing process seals the surface of the PA11. This prevents debris, reduces outgassing, and creates a high-emissivity surface that helps radiate heat away from your electronics into deep space.

Q: Does KSF Space offer launch services as well?

A: Yes, KSF Space provides a complete lifecycle from fabrication to launch. We help institutions, especially in developing countries, secure affordable rideshare opportunities.

Build Your Future in Orbit with KSF Space

The foundation of your space mission is the cubesat structure. Don’t settle for overpriced, heavy, or unverified frames. Choose the innovation, speed, and reliability of KSF Space.

For technical documentation, 3D CAD models, or a formal quote, reach out to our engineering department today.

Visit Us: www.ksf.space

General Inquiries: info@ksf.space